- Flight Reports

- Builder Spotlight

- Designer’s Notebook

- Customer Service

- Reset Password

- Guidelines for Writers

- Advertise with Kitplanes

- Industry News

- Kneeboard Notes

- Homebuilder’s Portal

- Completions

- Build Series

- Aircraft Buyer’s Guide

- Buying a Used Homebuilt

- Unairworthy!

- Sign in / Join

- Free Newsletter

- Give a Gift

- Buyer's Guides

- Engine Buyer's Guide

2024 Engine Buyer’s Guide

Costs are up and supplies remain tight, so plan accordingly.

Everyone flying—except birds and glider pilots—needs an engine. Whether you’re building a new kit or overhauling a flying airplane, inevitably you’ll need to decide which engine to use. Helping you with that decision is the point of this buyer’s guide.

State of the Market

Supply chain issues have been the main narrative around aircraft engines since COVID, but that story is winding down. Yes, supply remains tight on complete engines, cylinders and other parts, but enough parts are now available that demand is no longer running away from supply. Patience and ordering well ahead are still required (a year in advance remains a smart policy), but new engines and parts are being built.

Taking on increasing importance is cost. Inflation has definitely taken its toll, and aircraft engine prices—silly expensive to begin with—have risen to new levels of absurdity. The time-honored cost-saving tactic is forgoing brand-new engines in favor of rebuilding good cores. It’s the prime alternative to the stratospheric price of new engines.

The final word on pricing, however, is this: Powering your airplane is not the place to cut corners. From both safety and performance standpoints a quality powerplant pays for itself. Obviously reliability is crucial to safety, but it’s also important to match the engine to your airframe’s needs and provide you with the performance to make your overall investment worthwhile. Even though engines are a major cost, it’s smart to make all the investment necessary to arrive at the plane you want.

About This Guide

Engines in the 160- to 200-hp range dominate new Experimental builds. Add in more specialized aircraft on either side of that core market and engines between 100 and 350 hp account for nearly all Experimental/Amateur-Built aircraft coming together today, so that’s what we’ll highlight in this guide.

We also cover the odd turbojet, turboprop, radial, rotary, Wankel or what have you when they’re primed for Experimentals. The idea is to give a broad overview of the market along with enough specific information to help you narrow down your engine search.

To provide that broad outlook means we list current engines in the main text and put currently not for sale engines in the “ Circling the Airport ” sidebar. This catch-all includes engines just emerging onto the market along with old stalwarts long out of production but included because many remain in service, parts are available and you might run across them in your engine search. As always, this is a guide, not a catalog, so use it as a point of departure in your research.

Selecting an Engine

It sounds basic, but the first thing to know when engine shopping is yourself. Are you a practical sort building your first plane for general transportation and general entertainment flying? If so, stick to tried-and-true engines from popular companies. They’ll offer the most well-sorted, best-supported power options, which is what you need.

If you’re building a second or third airplane, or have a strong engineering background and are interested in something different and don’t mind the hiccups of off-Broadway engines, then go ahead and branch out if you want to. Just remember, specialty players require more hands-on involvement making brackets and such. This is fine for the experienced builder familiar with aircraft construction, operation and maintenance and backed by the necessary tools, but it’s overwhelming for a newbie.

Generally speaking, go with the airframe kit maker’s engine recommendation. These may include an auto conversion or small-volume engine maker, but if they offer a firewall-forward kit or tech support knowledgeable with your airframe then life is going to go easier. Every time and every place where you depart from the plans adds time and uncertainty. Maybe even risk.

About Those Clones

If you’re new to aviation engines, you’ll soon see Lycoming dominates the 160- to 200-hp center of the Experimental/Amateur-Built category. For the 180-hp market center Lycoming domination is so great that Continental and longtime parts supplier Superior make their own versions of Lycoming’s four-cylinders. Collectively these non-Lycoming “Lycomings” are casually referred to as clones but each has its own compelling upgrades and special features while remaining mainly interchangeable with Lycomings. They certainly are drop-in replacements with identical Dynafocal mounts and use standard cooling air baffles and so on. Continental sells their clone under the Titan brand name; Superior labels theirs as XP. (The Superior XP line has not been offered as a complete engine—parts are still being sold—for several years now, but you may come across these engines on the used market and Superior intends to offer complete engines again eventually.)

Auto Conversions

Converting automobile engines for aviation use is gaining popularity, mainly because auto engines keep getting better. Once very iffy foundations for an airplane engine, some of today’s auto engines can serve in light aircraft if properly prepared and supported. And yes, it’s that last part that typically causes grief.

Luckily, well-sorted auto engines and installation packages from AeroMomentum , Fly Corvair , Viking and others are available. You’ll benefit from the engineering put into the conversion package (for a penny on the dollar, we assure you), plus you can (and should) talk with earlier customers with real-world experience with the engine package. Also, stick close to auto conversions that retain stock core engines. Enthusiasts want hot-rod auto engines for aircraft use, but that’s a very bad idea. Stick to the proven stock engine configuration and leave hot rodding to racers who are used to dead-stick landings with oil on the windshield. While auto-to-airplane engines can work, it’s an immensely complex subject with absolutely no mercy for the neophyte trying to develop his own auto engine package.

Used, Overhauls, Rebuilds and Remanufactured

Another concept newcomers find surprising is the popularity of rebuilt, or what some might call “used,” engines on amateur-built planes. The terms may seem simple. New is new (all parts are new and newly assembled) and used is used (this engine may be currently flying in something else or has been resting at the back of the hangar since the Reagan administration). Where it gets confusing is the remanufactured category.

Remanufactured, rebuilt and overhauled engines have specific meanings when talking about certified engines. Remanufactured means an engine reset to factory-new specifications by the original engine manufacturer or one of their affiliate shops. Rebuilds involve a used engine rebuilt to new or close-to-new tolerances; the term is commonly used in casual conversation to mean any engine run through an engine shop. Overhauled is yet another legal definition in the certified world. It’s a used engine brought to within the minimum service limits defined by the manufacturer. In other words, an overhauled certified engine could be rather near to worn out after “rebuilding” and hopefully priced accordingly. Think of someone patching up an old airplane for sale. In practice, a rebuilt engine has many new parts in it. Typically the original crankcase and steel parts such as the crankshaft, connecting rods and often the timing gears are serviced and reused. Many minor parts are also reused. But the highly stressed cylinders and associated parts are normally brand-new. If you simply stick new cylinder assemblies on a used crankcase (typically without removing the crankcase from the airframe), that’s called a top overhaul . A tech might say such an engine was “topped.”

Rebuilding and topping Lycoming and Continental/Titan engines is absolutely par for the course. Rotax engines are also gaining popularity as rebuilds. Auto conversion engines are usually cheaper to simply replace with a new engine. Given the unregulated state of automotive engine rebuilding and the automated, close-tolerance methods of modern auto-engine production, it’s the smart way to go, too.

Where To Buy Airplane Engines

There are a surprising number of ways to purchase a general aviation engine. Often easiest and most cost effective is to order a new engine through your airplane’s kit manufacturer if they offer that service. Just check the box on the order form and write the check.

Next in convenience is ordering an engine directly from an engine manufacturer or one of their dealers. Be aware that engine makers don’t keep engines in stock. There are too many engine variations and too few sales to keep anything in stock so your engine will be built to order. And here you have the choice of a bone-stock engine as you might find on a Piper, or a non-certified, custom engine. Lycoming’s Thunderbolt division provides the custom engines under that brand, while Titan is the name for Continental’s version of custom engines. At the other extreme, Rotax is right at home in both the certified and Experimental markets and has no need for an in-house boutique or separately named engines. A Rotax is a Rotax . Well, at least until it is modified by Edge Performance and becomes an Edge engine, but that’s an entirely separate company. Rotaxes are sold via several distributors in North America; see the Rotax heading below.

Non-Factory Sources

Once past factory-new engines we enter the realm of rebuild shops. The purchasing process becomes less formal and more customized because options are what rebuild shops excel at. Rebuild shops range from large businesses with over 30 employees that offer a warranty to small man-in-a-hangar operations. Some of the larger shops are well-known such as, but not limited to, Aero Sport Power , Barrett Precision Engines , Ly-Con Aircraft Engines and Pinnacle Aircraft Engines . All of these shops overhaul certified engines as their bread and butter, but also specialize in Experimental sport, backcountry, racing, aerobatic and other performance powerplants. Some make their own line of special parts and have hot rod knowledge even the factories likely don’t possess, plus they offer services such as dynamometer break-in or small parts manufacturing. If you’re looking for something special, racy or show-worthy these are where to go.

Size and longevity are good signs in an engine shop, but smaller shops can do good work, too. It’s worth noting the truly small operations don’t have machining capabilities and must work with specialist firms or one of the big engine shops for things such as connecting rod reconditioning, balancing, crankshaft or lifter grinding, engine case machine work and many other functions—which is fine. What these small shops really do is provide a valuable service sorting through all the possibilities with you, providing a local parts source and final assembly of an engine using parts machined elsewhere. Where these small shops source their machine work and what volume of work they do give a clue as to their viability. Finally, they might be a little faster to deliver an engine than the bigger shops depending on workload.

That’s the broad overview. Let’s get into the engines available today.

Back to the 2024 Engine Buyer’s Guide Index

RELATED ARTICLES MORE FROM AUTHOR

EFIS Roundup 2024

Hawking That New Engine

What’s Up In the Experimental Engine Market

Lycoming Thunderbolt Engines Update

Where Are the Instructions?

OSH Live Interview with Rotax’s Marc Becker

Viking’s Latest—And Some Zodiac Eye Candy

Near Perfect, But Nothing Fancy

Take a Lap!

Tom, EPA Power (Rotax substitute) was recommended to me as I consider powerplants for my Flying Legends Tucano Replica. If you happen to talk with them they’d be a good addition to this guide. https://www.epapower.com/Avio.html

LEAVE A REPLY Cancel reply

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

In Case You Missed It

I Want My ADS-B!

Boring on the Vertical

Building the 750SD XTREME: Part 4

Homebuilt O2

- Privacy Policy

- Terms of Use

Small Aircraft Engines

The PBS TJ150 jet engine was developed for target drones and UAVs. Its advantage is its compact design, low weight with a thrust of up to 1,500 N, and low fuel consumption in the given power category. The generator output is 750 W. One of the PBS TJ150 engine versions enables landing on water. The PBS TJ150 engine is a single-shaft jet engine consisting of a radial compressor, radial and axial diffuser, annular combustion chamber, axial turbine and a fixed outlet nozzle. Standard accessories: included: control system (FADEC), ignition, connecting cable Optional accessories: electromagnetic fuel valve, fuel filter, control lever, signalling panel, boost pump, reduction valve, converter CAN, converter CAN-USB, user software.

The PBS TJ100 is a 4th generation jet engine that is particularly suitable for UAVs, target drones and other unmanned applications. The PBS TJ100 engine is of a compact design and has an excellent power-to-weight ratio of up to 292 lbf (1,300 N) with low fuel consumption for its output category. This engine is also suitable for landing on water.

PBS TJ40-G1

The PBS TJ40 advantage is the low weight of 3.3 kg and a thrust of 395 N. The PBS TJ40-G1 jet engine is a single-shaft engine with a one-stage radial compressor, radial and axial diffuser, annular combustion chamber, one-stage axial turbine and outlet nozzle. The output of the generator is 150 W.

is a turboprop engine especially suited to small aircrafts and other manned and unmanned vehicles. These can be used for rescue services, police or reconnaissance purposes and also in agriculture. They can also be used in military applications for other purposes and for Vertical Take-Off and Landing UAVs. The main advantage of this engine is its low weight with a power of 241 HP (180 kW) and its capacity to achieve flight levels of 29,520 ft (9,000 m) with a maximum starting height of 19,680 ft (6,000 m). The system is designed so that the engine can be placed in the aircraft in either pusher or tractor mode.

is a turboshaft engine. This type of engine emerged with the development of modern helicopters. The engine is suitable for smaller and lighter helicopters or for unmanned aerial vehicles. These can be used for rescue services, police or reconnaissance purposes and also in agriculture. The advantage of the engine lies in its small installation dimensions, low weight and high static performance at 241 HP (180 kW) with the capacity to achieve flight levels of up to 29,520 ft (9,000 m) and a maximum starting height of 19,680 ft (6,000 m).

NASA is Developing Future Propulsion Systems and Improving Sustainability with This Pint-Sized Jet Engine

A small-scale jet engine compact enough to fit on a tabletop is helping to make the future of aviation more sustainable, according to NASA engineers currently involved in tests that could help pave the way toward new aircraft propulsion systems of the coming decades.

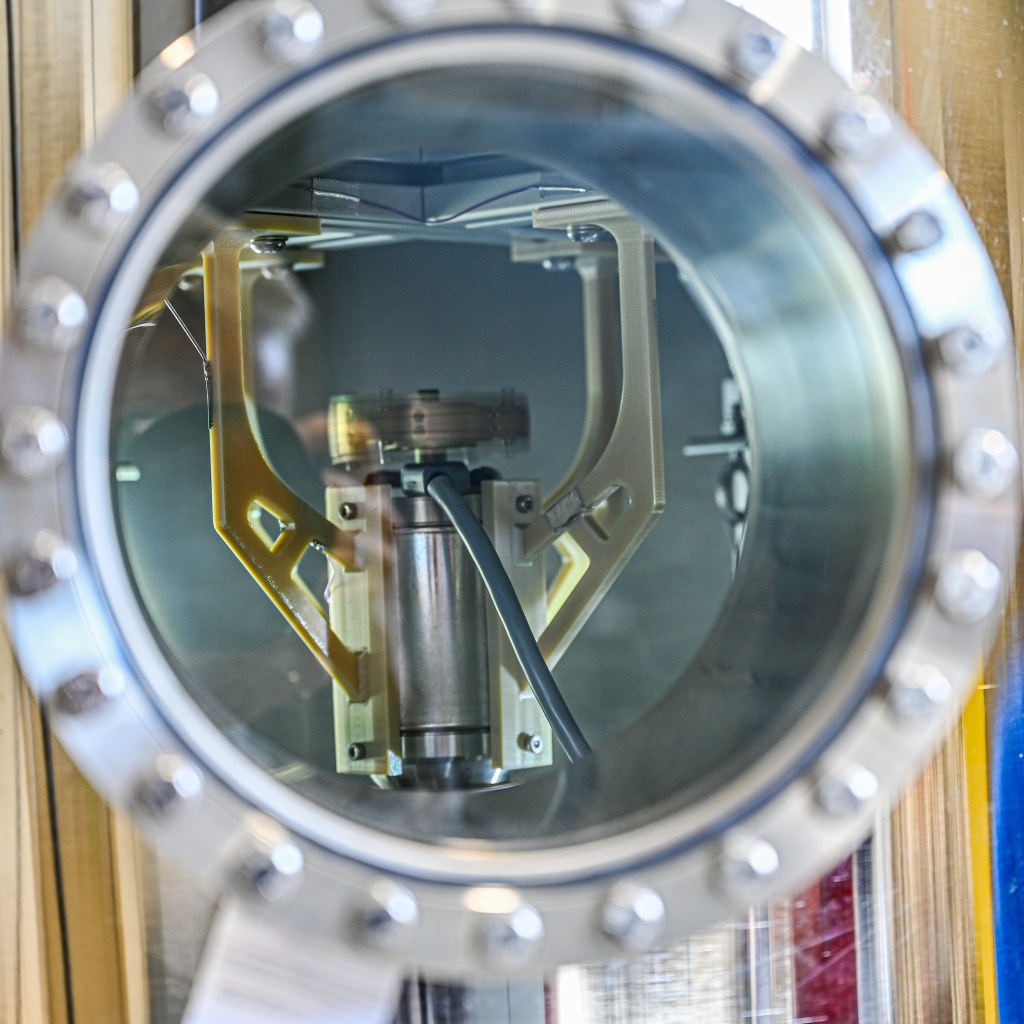

The DGEN380 Aero-Propulsion Research Turbofan (DART) is less than 4.5 feet in length, making it half the size of engines on moderately sized aircraft, and NASA engineers are now using the miniature engine to help to reduce costs associated with using a full-sized jet engine for research and testing purposes.

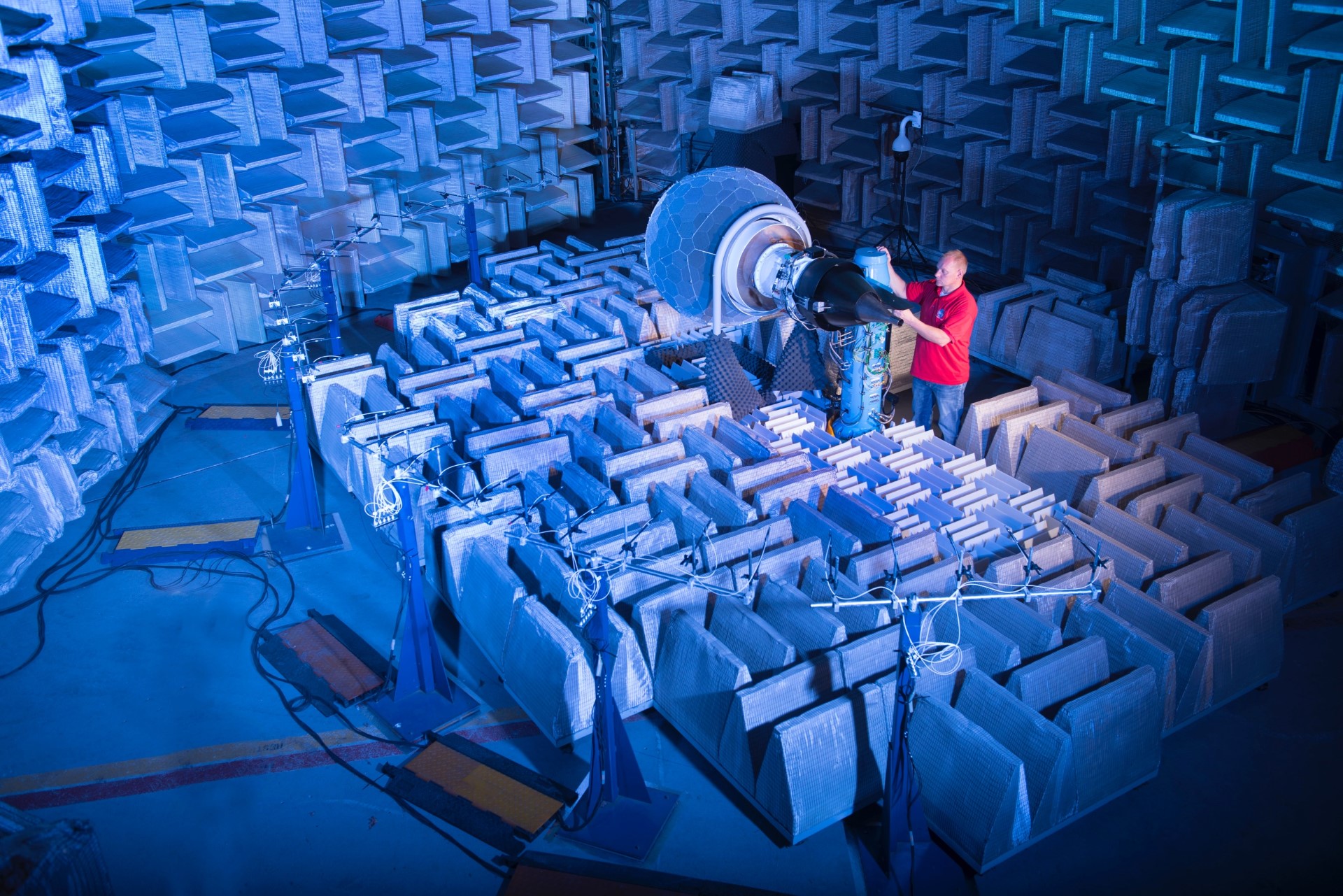

Currently, experiments with the small jet engine are being undertaken at NASA’s Glenn Research Center in Cleveland, within the facility’s Aero-Acoustic Propulsion Laboratory . Home of the Nozzle Acoustic Test Rig (NATR) developed for tests involving acoustic and aerodynamic aspects of advanced nozzle concepts, the facility also employs the Small Hot Jet acoustic Rig (SHJAR) which employs lasers to test turbulence studies and gauge thrust performance.

Although it shares a similar name with NASA’s Double Asteroid Redirection Test , the entirely separate DART engine was assembled by French aerospace company Akira (formerly known as Price Induction), and since its acquisition by NASA seven years ago, has become a key component alongside several new technologies NASA is employing to aid in making the aviation industry more sustainable.

In addition to the benefits of its compact size, DART allows an accessible way to gauge new technologies that aren’t yet at full-scale operation, according to NASA Glenn engineer Dan Sutliff, who is currently the coordinator for research with the DART engine program.

DART has already proven useful during studies involving several components of NASA operations, which include the space agency’s ongoing efforts to reduce the noise produced by aircraft engines that will make future airliners quieter.

In addition to cutting back on noise pollution, NASA engineers are also looking ahead toward developing highly efficient next-generation airliners that will be used in the decades ahead, with current timelines aiming for their institution by the 2030s.

Before testing these ultra-efficient aircraft engines in NASA’s larger facilities, initial experiments with the DART engine could pave the way toward meeting those intended goals.

“DART is a critical bridge between a design and a wind tunnel test,” Sutliff recently said in a statement, adding that technologies that have been tested at Glenn’s Aero-Acoustic Propulsion Laboratory in the past have shown to have a better shot at being implemented on new types of aircraft engines.

Capable of generating 570 lbs of thrust, DART’s DGEN 380 engine contains five main turbo machinery components. The unit’s high-pressure turbine is connected by a high-pressure compressor through a high-speed shaft, all of which are complemented by a corresponding low-pressure turbine and shaft that drives the engine’s fan with help from a speed reducer gearbox. The DGEN 380 also employs a 14-inch fan which can attain maximum speeds in subsonic ranges.

“SOAR” LiDAR-UAV System Promises to Transform Military and Civilian Applications with Faster, Smarter 3D Aerial Reconnaissance

However, part of what makes the DART engine particularly useful in the testing environment is its ability to measure the amount of air that passes through the main core engine’s turbofan, as opposed to actually going into it. This is referred to as its bypass ratio, and having a higher ratio makes DART’s functionality similar to the ratios on many current aircraft engines in use.

Higher bypass ratios help engines maintain fuel efficiency and allow DART to be an ideal starting point for experiments with new varieties of propulsion. Additionally, the small engine’s efficiency makes it ideal for tests in advance of the development of small-core jet engines that will likely begin to power aircraft by the next decade.

Further benefits of DART’s economical operation allow studies involving a range of other aviation technologies, which include engine control development, sensors, and instrumentation studies, installation effects of various components, as well as special coatings used to protect engine components and a range of other tests.

“The test rig helps NASA save resources and contribute to protecting our environment,” Sutliff said.

Micah Hanks is the Editor-in-Chief and Co-Founder of The Debrief. He can be reached by email at [email protected] . Follow his work at micahhanks.com and on X: @MicahHanks .

Suggested Searches

Climate Change

- Expedition 64

- Mars perseverance

- SpaceX Crew-2

- International Space Station

- View All Topics A-Z

Humans in Space

Earth & Climate

The solar system, the universe.

- Aeronautics

Learning Resources

News & events.

NASA’s Curiosity Mars Rover Takes a Last Look at Mysterious Sulfur

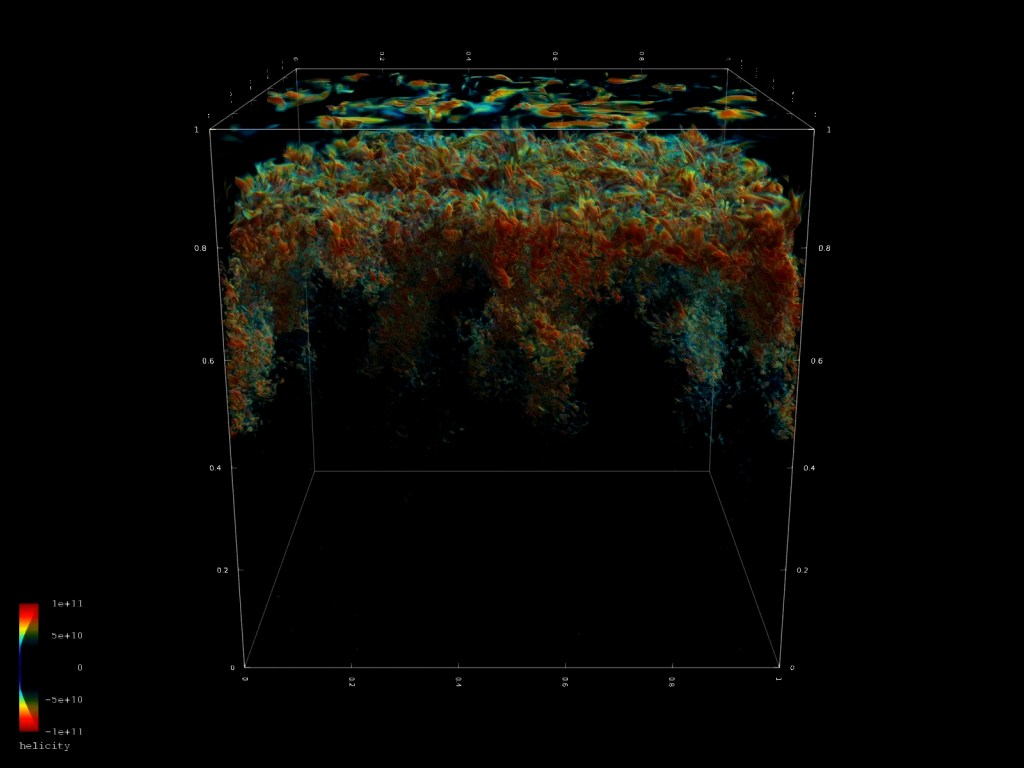

Hollywood Techniques Help NASA Visualize Supercomputing Data

What’s Up: November 2024 Skywatching Tips from NASA

- Search All NASA Missions

- A to Z List of Missions

- Upcoming Launches and Landings

- Spaceships and Rockets

- Communicating with Missions

- James Webb Space Telescope

- Hubble Space Telescope

- Why Go to Space

- Commercial Space

- Destinations

- Living in Space

- Explore Earth Science

- Earth, Our Planet

- Earth Science in Action

- Earth Multimedia

- Earth Science Researchers

- Pluto & Dwarf Planets

- Asteroids, Comets & Meteors

- The Kuiper Belt

- The Oort Cloud

- Skywatching

- The Search for Life in the Universe

- Black Holes

- The Big Bang

- Dark Energy & Dark Matter

- Earth Science

- Planetary Science

- Astrophysics & Space Science

- The Sun & Heliophysics

- Biological & Physical Sciences

- Lunar Science

- Citizen Science

- Astromaterials

- Aeronautics Research

- Human Space Travel Research

- Science in the Air

- NASA Aircraft

- Flight Innovation

- Supersonic Flight

- Air Traffic Solutions

- Green Aviation Tech

- Drones & You

- Technology Transfer & Spinoffs

- Space Travel Technology

- Technology Living in Space

- Manufacturing and Materials

- Science Instruments

- For Kids and Students

- For Educators

- For Colleges and Universities

- For Professionals

- Science for Everyone

- Requests for Exhibits, Artifacts, or Speakers

- STEM Engagement at NASA

- NASA's Impacts

- Centers and Facilities

- Directorates

- Organizations

- People of NASA

- Internships

- Our History

- Doing Business with NASA

- Get Involved

NASA en Español

- Aeronáutica

- Ciencias Terrestres

- Sistema Solar

- All NASA News

- Video Series on NASA+

- Newsletters

- Social Media

- Media Resources

- Upcoming Launches & Landings

- Virtual Guest Program

- Image of the Day

- Sounds and Ringtones

- Interactives

- STEM Multimedia

Hubble Takes a Look at Tangled Galaxies

NASA’s EMIT Will Explore Diverse Science Questions on Extended Mission

NASA Marshall Thermal Engineering Lab Provides Key Insight to Human Landing System

Preguntas frecuentes: La verdadera historia del cuidado de la salud de los astronautas en el espacio

Faq: the real story about astronaut health care in space.

Amendment 70: New Opportunity: A.62 FarmFlux Science Team

5 Surprising NASA Heliophysics Discoveries Not Related to the Sun

NASA’s Brad Doorn Brings Farm Belt Wisdom to Space-Age Agriculture

Ready, Set, Action! Our Sun is the Star in Dazzling Simulation

NASA Ocean World Explorers Have to Swim Before They Can Fly

Hubble Captures an Edge-On Spiral with Curve Appeal

NASA’s Hubble Finds Sizzling Details About Young Star FU Orionis

NASA’s Chandra, Hubble Tune Into ‘Flame-Throwing’ Guitar Nebula

NASA: Mystery of Life’s Handedness Deepens

NASA Engineer Carries Indigenous Roots into New Aviation Era

NASA Electric Aircraft Testbed (NEAT)

Dynamic Spin Rig Publications

What is BioSentinel?

Making Mars’ Moons: Supercomputers Offer ‘Disruptive’ New Explanation

Why NASA Is a Great Place to Launch Your Career

Northwestern University Takes Top Honors in BIG Idea Lunar Inflatables Challenge

15 Years Ago: STS-129 Delivers Cargo on the Third Utilization and Logistics Flight

El X-59 enciende su motor por primera vez rumbo al despegue

La NASA lleva un dron y un rover espacial a un espectáculo aéreo

Destacado de la NASA: Felipe Valdez, un ingeniero inspirador

Nasa uses small engine to enhance sustainable jet research.

- Aeronautics Research Mission Directorate

Located inside a high-tech NASA laboratory in Cleveland is something you could almost miss at first glance: a small-scale, fully operational jet engine to test new technology that could make aviation more sustainable .

The engine’s smaller size and modestly equipped test stand means researchers and engineers can try out newly designed engine components less expensively compared to using a more costly full-scale jet engine test rig.

Named DGEN380 Aero-Propulsion Research Turbofan , or DART, the engine is tiny enough to fit on a kitchen table, measuring at just 4.3 feet (1.3 meters) long. That’s about half the length of engines used on single-aisle airliners.

DART – not to be confused with NASA’s asteroid redirect mission of the same name – enables the agency to boost its sustainable aviation technology research because of its accessibility.

A hidden gem located inside the Aero-Acoustic Propulsion Laboratory at NASA’s Glenn Research Center in Cleveland, the DART engine was made by a French company named Price Induction (now Akira) and was acquired by NASA in 2017.

“DART’s small size makes it appealing,” said Dan Sutliff, who coordinates research for the engine at NASA Glenn. “It’s a great way to explore new technology that hasn’t yet reached the level of a full-scale operation.”

Small Steps Towards Big Goals

Several key NASA activities studying jet engines used DART in the past.

For example, it helped researchers learn more about incorporating materials that can help reduce engine noise. These technologies could be incorporated for use in next-generation airliners to make them quieter.

Now, NASA researchers plan to use the DART engine to investigate ideas that could help develop new ultra-efficient airliners for use during the 2030s and beyond. If all goes well, the technology could proceed to more exhaustive tests involving larger facilities such as NASA’s wind tunnels.

“DART is a critical bridge between a design and a wind tunnel test,” Sutliff said. “Technologies that work well here have a greater chance of achieving successful inclusion on future aircraft engines. The test rig helps NASA save resources and contribute to protecting our environment.”

Among its features, DART has a high bypass ratio, which is a measure of how much air passes through the turbofan and around the main core of the engine as opposed to entering it. Having a high bypass ratio means that DART is more characteristic of larger high-bypass ratio engines on commercial aircraft.

This design is more fuel efficient than other jet engines and makes DART ideal for testing new propulsion methods alongside NASA’s efforts in developing a small-core, fuel efficient jet engine for commercial airliners in the 2030s.

The DART engine also can test many other aspects of a jet engine including engine noise, operating controls, coatings used to protect engine parts, sensors and other instrumentation, and much more.

More information can be found on NASA’s Aero-Acoustic Propulsion Laboratory webpage .

About the Author

John Gould is a member of NASA Aeronautics' Strategic Communications team at NASA Headquarters in Washington, DC. He is dedicated to public service and NASA’s leading role in scientific exploration. Prior to working for NASA Aeronautics, he was a spaceflight historian and writer, having a lifelong passion for space and aviation.

Explore More

Updates from NASA’s HyTEC Engine Core Project Show Progress

Sustainable Flight National Partnership

University Researchers Moving Electrified Aviation Forward with NASA

Discover more topics from nasa.

Aeronautics STEM

Related Terms

- Aeronautics Technology

- Glenn Research Center

IMAGES

VIDEO

COMMENTS

The new companies touting these new entries are quoting prices radically lower than the only similar jet engine so far available, the PBS TJ100. We have to wait and see if these new turbines truly go on sale and how they do. ... Because the market for Experimental aircraft has grown to such a significant proportion of the new-airplane world ...

We can help design and build your experimental aircraft engine. We specialize in all your experimental piston engine needs from brand new '0' time custom engines, to overhauls, prop strikes and repairing your cylinders and components. We are a global leader in customizing, designing and building high-performance experimental aircraft ...

The two shown at Air Venture were said to be complete, running engines and a third has been flying on a Bristol in England. Now we can add Greece to the countries joining the modern kit plane era, for that is where Heron is starting production of a decidedly compact 130 hp turboprop for the experimental market by the end of 2022.

Some of the larger shops are well-known such as, but not limited to, Aero Sport Power, Barrett Precision Engines, Ly-Con Aircraft Engines and Pinnacle Aircraft Engines. All of these shops overhaul certified engines as their bread and butter, but also specialize in Experimental sport, backcountry, racing, aerobatic and other performance powerplants.

In the near-ish future, Brooke intends to build an experimental airframe powered by four Astro Mechanica turboelectric adaptive jet engines and two GE CT7 engines and flying non-stop-supersonic ...

During development PBS AEROSPACE focused on smaller turbine engines used mainly in smaller and experimental aircraft, helicopters and unmanned aerial vehicles. ... output is 750 W. One of the PBS TJ150 engine versions enables landing on water. The PBS TJ150 engine is a single-shaft jet engine consisting of a radial compressor, radial and axial ...

The new model aircraft with the turbine engine is Rolls Royce RR-500. It is one of the engines that can be exclusively installed in experimental aircraft builders in their designs. The piece's characteristics are that it can power a four-place aircraft, including the improved global fuel availability. Walter M601

The DGEN380 Aero-Propulsion Research Turbofan (DART) is less than 4.5 feet in length, making it half the size of engines on moderately sized aircraft, and NASA engineers are now using the miniature engine to help to reduce costs associated with using a full-sized jet engine for research and testing purposes.

Located inside a high-tech NASA laboratory in Cleveland is something you could almost miss at first glance: a small-scale, fully operational jet engine to test new technology that could make aviation more sustainable.. The engine's smaller size and modestly equipped test stand means researchers and engineers can try out newly designed engine components less expensively compared to using a ...

NASA to design fuel-efficient jet engines by 2030 NASA engineers aim to use the engine in their efforts to develop a new small-core, fuel-efficient jet engine for commercial airliners by the 2030s.